Comparing US and European crash barrier standards

First published in The Global Road Safety Review 2015 as Comparing barrier standards

Comparing US and European crash barrier protection standards highlights key differences in vehicle types – *Luigi Grassia, *Mauro Corsanici

Most of the crash cushions available on the market are designed according to one of the major international standards, namely EN 1317 and NCHRP 350. EN 1317 is the European standard and it is still used to certify new products, whereas NCHRP 350 is the US standard and was used up to 2010 to certify road safety products but now it has been replaced by the MASH standard.

It is of interest to compare the requirements of the two standards with respect to their recommendations about the design of crash cushions. In particular this paper reports a comparison between the requirements to design a non-gating TL3 crash cushion according to NCHRP 350 and to design a redirective 110km/h crash cushion according to EN 1317.

NCHRP 350 prescribes to test crash cushions with two different kinds of cars: an 820kg small car and a 2tonne pick-up truck. These vehicles are both used to certify the crash cushions for three different levels of velocity, namely 50km/h (TL1), 70km/h (TL2) and 100km/h (TL3).

EN 1317 prescribes to run crash tests with three different types of cars: a 900kg small car, a 1.3tonne medium car and a 1.5tonne large car. Crash cushions can be tested at four different velocities, namely, 50km/h, 80km/h, 100km/h and 110km/h. The small car is used in the test at 50km/h, with the small and medium cars used for 80km/h and 100km/h tests and the small and large cars used for the 110km/h test.

The capacity test is defined as the crash test characterised by the maximum level of energy in the test matrix for that level of velocity: it is the head-on impact of the heavier vehicle for the level of velocity under consideration. In NCHRP 350 the heavier vehicle is the pick-up at each velocity, whereas in the EN 1317 the heavier vehicle depends on level of velocity.

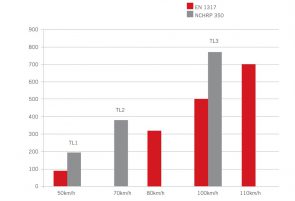

In figure 1 the energy is shown for each capacity test for each level of velocity in the two standards. The gray bars are for NCHRP 350, whereas the red bars are for EN 1317.

Figure 1

Comparison of the energy in kJ involved in the capacity test at each level of velocity: gray – NCHRP 350; red – EN 1317.

From Figure 1 it appears that the energy involved in the impacts are comparable for TL2 (NCHRP350) and 80km/h (EN1317) but also for TL3 (NCHRP) and 110km/h (NCHRP). It is necessary to compare the requirements of the two standards.

The capacity test for TL3 requires absorbing 70kJ of energy more than the 110km/h. The nominal energy in the headon impact of the 2tonne pick-up travelling at 100km/h is 770kJ whereas the nominal energy involved in the head-on impact at 110km/h according to EN 1317 is 700kJ.

This means that crash cushions designed according to the European standards absorb 10% energy less than crash cushions designed according the US standards. This does not mean however that 350 crash cushions are safer than 1317 crash cushions. In order to stress this point it is possible to compare the impacts of two vehicles with the same kinetic energy but travelling at two different speeds.

A train with a mass of 90tonnes travelling at 4.7km/h will have the same kinetic energy characteristic as a 200kg motorcycle travelling at 315km/h.

But assuming that these vehicles were to impact with a TL3 barrier, the results would be very different. It is of note that the speed of deceleration is crucial to the injuries any passengers or drivers receive.

This example is useful to understand an important aspect related to the difference between the NCHRP 350 and EN 1317. It is true that the energetic level of NCHRP 350 is larger than that of EN 1317 by 70kJ. However, the EN 1317 test deals with an impact at 110km/h, a speed of 10km/h greater than for NCHRP 350, and the higher speed results in a greater deceleration.

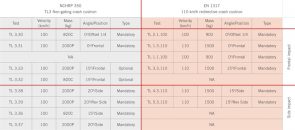

In Figure 2, the crash tests required by the two standards to test non-gating TL3 and redirective 110km/h crash cushions are shown. The table shows the tests required by NCHRP 350 on the left side and the tests required by the EN 1317 are reported on the right side. The frontal tests are shown at the top and the lateral tests at the bottom.

Figure 2

Comparison of the crash tests required to certify a TL3 non-gating crash cushion (left side of the table) and a redirective 110km/h crash cushion (right side of the table).

From Figure 2 it appears that the NCHRP 350 standard requires running only two frontal crash tests, whereas EN 1317 requires running four frontal impacts. On the other hand, EN 1317 requires running only two side impacts, whereas the NCHRP 350 requires running four side impacts. The maximum kinetic energy involved in the frontal impact is 770kJ for NCHRP 350 and 700kJ for EN 1317. Referring to the side impacts the difference in terms of energy between the two standards increases: the kinetic energy calculated using only the transverse component of the velocity is 90kJ required by NCHRP 350, whereas that required by EN 1317 is only 47kJ. As a result, the side impacts for NCHRP 350 are for much greater forces than EN 1317. However it is worth noting that for the NCHRP 350 standard, it is not mandatory to run the head-on impact with a small car and the angle impact at 15° on the front. The latter is the most difficult crash test to pass from a perspective of biomechanical parameters due to the deceleration and occupant impact velocity.

Evaluation of crash test data is crucial. But before any kind of crash test, accelerometers must be installed that correspond to the centre of gravity of the vehicle. These accelerometers measure deceleration during the impact of the vehicle against the crash cushion. Both standards are designed to record the longitudinal (X), transversal (Y) and vertical (Z) acceleration. The way the data is recorded is the same in the two standards, but there are differences in the way this data is used to calculate the various biomechanical parameters.

The parameters calculated are the occupant impact velocity (OIV) and the occupant ridedown acceleration (ORA) for the NCHRP 350 standard, and the theoretical head impact velocity (THIV) and acceleration severity index (ASI) for the EN 1317. The OIV and THIV refer to the theoretical impact velocity of the occupant inside the passenger compartment, whereas ORA and ASI refer to the average deceleration of the centre of gravity of the car.

In both standards, the occupant of the vehicle is considered as an object free to move inside the passenger compartment. The head will continue to move at the nominal velocity of impact due to inertial effect whereas the compartment of the vehicle around it will begin to decelerate due to the opposing force applied on the vehicle by the impacted safety device. Consequently it is possible to define a time at which the head hits the passenger compartment, this is called the flight time and is indicated by t*. Both the two standards are designed to calculate t* as the time at which the occupant (or the occupant’s head) inside the vehicle has travelled either 0.6m in the longitudinal direction or 0.3m in the lateral direction.

The OIV is defined as the largest value between the two components of the occupant velocity (Vx and Vy) at t*. The THIV is defined as the resultant of the occupant velocity at t*.

At this point, two main differences arise between the two standards: the first difference is that NCHRP 350 considers the components of velocity separately, whereas EN 1317 considers the components of velocity together. The approach followed by the EN 1317 is more precise than that used by NCHRP 350 because the occupant feels the two components of the velocity simultaneously and not separately as assumed by the NCHRP 350 standard. Combining these factors is important: for example, assuming that Vx and Vy at t* are both equal to 43.2km/h this gives an OIV of 43.2 compliant with the requirements of the NCHRP 350 standard and a THIV of 61km/h that is not compliant with the requirements of EN 1317. This means that a crash test compliant with the NCHRP 350 standard would be not be compliant with EN 1317. The second difference looks at the limits set out by the two standards for OIV and THIV.

In this, the NCHRP 350 standard sets the same limit of 43.2km/h for OIV in both the frontal and side crash tests. However, EN 1317 sets two different limits for THIV in the frontal and side tests. The limit for the frontal test is 44km/h and in the side test the limit is 33km/h. As a result the THIV and the OIV limits are almost the same for the frontal impact. But for the side impact, the EN 1317 limit is more conservative and safer than that of NCHRP 350. In addition, NCHRP 350 only evaluates the longitudinal component of the velocity.

Once the limit for the occupant velocity is fixed, it becomes more difficult to stay within the limits should initial velocity increase. This means that from the THIV or OIV point of view it is more difficult to pass a test at 110km/h for EN1317 than at 100km/h for NCHRP350, even if the energy involved in the impact is almost the same.

ORA and ASI are both a measure of the average deceleration of the vehicle during the impact against the safety device. The starting data for the calculation of the two parameters are the data coming from the accelerometers.

In the ORA calculation only the X and Y components of the acceleration are taken in to account. The rough data coming from the accelerometer is filtered and then analysed in the X and Y directions. Only the ridedown accelerations after the flight time t* that define the OIV are considered. In order to pass the crash test, the average ridedown acceleration after the flight time t* must be less than 20g in both X and Y directions. There is no limit for the average acceleration in the time window from the instant of the impact and the flight time t*. Tests on safety devices like crash cushions generally have a duration of about 0.3 seconds. Experience shows that the flight time is usually confined to within 0.1 and 0.13 seconds. This means that at least in one third of the overall impact, the deceleration can attain any value.

The ASI is computed considering all the three components (X, Y and Z) of the accelerations as measured by the accelerometer. At first the rough data is filtered. Finally, the filtered components of the accelerations (ax, ay, az) are combined together to evaluate the ASI.

The maximum admissible value of the ASI for crash cushions is equal to 1.4. This means that in the framework of the EN 1317 the maximum admissible average acceleration in the longitudinal direction is 16.8g and in the lateral direction is 12.6g. Both values are well below the limits of 20g fixed by the NCHRP 350. More importantly, the EN 1317 standard considers the accelerations in x and y directions combined together in the ASI formula, whereas NCHRP 350 considers accelerations in x and y directions separately.

This means that a test with ax=20 g and ay=20g is compliant with NCHRP whereas to be compliant with EN 1317 if ax=16.8 g, then ay and az must be zero (or equivalently if ay=12.6 g, then ax and ay must be equal to zero). These considerations show that an accelerometer signal compliant with EN 1317 will be also compliant with NCHRP 350. But an accelerometer signal compliant with NCHRP 350 may be not compliant with EN 1317 because the acceleration limits of NCHRP 350 are larger than those of EN 1317.

In addition to the evaluation of the biomechanical parameters (ORA-ASI and OIV and THIV) the two standards reveal other evaluation criteria. Referring to these concerns, the requirements of the two standards are very similar. Both standards prescribe that detached elements from the test article should not penetrate the occupant compartment, present a hazard to traffic, or block the driver’s vision and that the vehicle should remain upright.

The only important difference between the two standards about the vehicle behaviour regards the exit trajectory of the vehicle after the impact. NCHRP 350 says that after the collision it is preferable that the vehicle trajectory does not intrude into adjacent traffic lanes and that the exit angle should preferably be less than 60% of the test impact angle, measured at time of loss of contact with the test device. EN 1317 says that in any tests, the wheels of the vehicle should not encroach the line of the exit box, unless the velocity of the vehicle centre of mass is less than or equal to 10% of prescribed impact speed.

Overall it is clear that the NCHRP 350 standard is stricter than EN 1317 with respect to the capacity to absorb energy involved in the frontal impact and especially in the lateral impacts. On the other hand EN 1317 is stricter than NCHRP350 with respect to the evaluation criteria because the limits of the biomechanical parameters of the EN1317 are lower than those for the NCHRP 350. This is because the NCHRP 350 standard permits higher occupant impact velocities and greater average occupant decelerations. In all, NCHRP requires stronger and stiffer crash cushions, whereas EN1317 is more focused on the forces experienced by vehicle occupants.

It is however feasible to design a crash cushion that is compliant to both standards. This can be carried out by testing the safety device according to the EN1317 and then running two additional crash tests. The first is a capacity crash test in order to fill the gap between the energies of the frontal impact in the two standard. Running a TL3.31 test on an EN1317 product is sufficient to show that the system is able to fill the energy gap.

The second test is for a side impact to show that the EN1317 device is able to resist at the greater forces typical of the NCHRP350 side impacts. Among the side impacts of the NCHRP 350, the toughest is for the TL3.37. If an EN 1317 crash cushion is able to pass also a TL3.37 test, it will be also compliant with the other requirements of the NCHRP 350 related to the side tests.

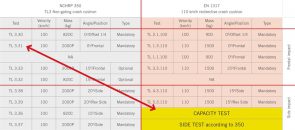

Figure 3

Comparison of the crash tests required to certify a TL3 non gating crash cushion (left side of the table) and a redirective 110km/h crash cushion (right side of the table): in yellow the two additional crash tests that could make an EN1317 crash cushion also compliant with NCHRP350.

*Luigi Grassia, Departement of Industrial and Information Engineering, The Second University of Naples, Aversa, Italy

*Mauro Corsanici, Research and Development Department, Industry AMS srl, Marcianise, Italy